Extend the life of your roads with

Velocity Preservation

Prevention is better than cure. Velocity is helping local authorities to extend the life of assets that are currently in a good condition with the application of EVERPHALT®, a proven preservative treatment.

EVERPHALT® is applied to pavements in good to fair condition benefiting from protecting. Depending on local climate and traffic loads, pavements typically retain their treated condition for 5 to 7 years or more. Repeat treatments, typically at progressively lower application rates, continue to preserve pavements for further 5 to 7 years periods in substantively the same condition as the first and previous treatments.

With our knowledge and experience of maintaining the UK’s local road network, we deliver a turn-key service for effective preservation projects. Our dedicated team manage projects from initial inspection to delivery including all elements of the supply chain.

Customers can be confident they are in good hands, with the knowledge that their assets are protected with a proven product.

Benefits

The proven product for preservation

HAPAS approved and REACH compliant EVERPHALT® is a solvent-based Uintaite Gilsonite®fortified bituminous asphalt preservative for which Velocity holds exclusive delivery rights to all roads and highways in the UK. Gilsonite® fortified formulations were introduced to the UK in 2003 by the founders of CNRG Technologies whose continuous refinement of the chemistry and manufacturing process is now embodied in EVERPHALT®.

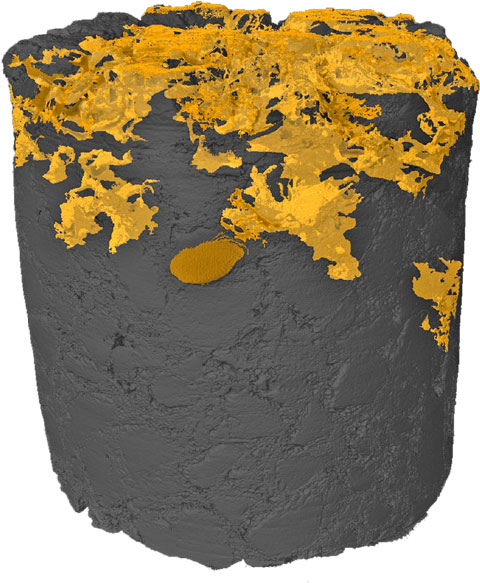

X-ray CT scanning on treated SMA cores has shown the porosity in the top half of the surface course is reduced by up to 35% without negatively affecting surface texture. That means that a surface course with 7% in-situ voids can be reduced to 5%, significantly slowing the ageing process.

How Rhinophalt Works

Rhinophalt is best applied around two-years before intervention is required.

It can penetrate up to 30mm on aged asphalt surfaces through micro-cracks and interconnecting voids, forming a hard seal.

Once treated, the ingress of water, salts and contaminants is reduced, resulting in fewer defects and potholes, keeping the asphalt in good condition for longer.

- Improves retention of aggregate

- More resistant to wear than new bitumen

- Stops further deterioration of the asphalt surface

Application

Installation is carried out with just one machine, usually operating at night under road closure.

Following a pre-sweep, the product is quietly sprayed on to the road surface with just one pass of the machine. No compaction of heavy equipment is required, and because the profile of the road is maintained there is no need to raise ironworks, kerb heights or thresholds.

Surface texture is maintained and grip restored with the application of a fine grit/dust.

Up to 30,000m2 can be treated per shift, with no need for aftercare or remedial works.

A rapid curing time means that line markings can be applied in the same closure window, with the road reopened for traffic comfortably in time for traffic.

ISO 9001:2015

ISO 14001:2015

ISO 45001

RSTA Member

NHSS 13